HardyTest D700

Digital hardness tester HardyTest D700 for 6 external impact device types and integrated printer

The hardness tester HardyTest D700 measures the hardness of a large number of materials in six different hardness units. A selection of six impact device types allows the hardness measurement of specific material shapes in different hardness levels. In addition, the hardness tester is equipped with an integrated printer and the ability to transfer data to the PC.

The hardness tester HardyTest D700 along with its brother the HardyTest D600 belong to the high class in hardness measurements. It was developed to meet all requirements in professional hardness testing.

The HardyTest D700 is applicable for almost all hardness measurements on ferrous and non-ferrous metals. For use in the power plant industry, petrochemicals, apparatus, vehicle and mechanical engineering, quality control, steelworks, and more, the hardness tester HardyTest D700 has proven to be excellent.

Properties

- 6 impact device types (D, DC, DL, D+15, C and G) available for special applications with automatic identification on the device

- integrated printer

- wide measuring range: 170-960 HLD (Leeb hardness test principle)

- All hardness units: HL (Leeb), HB (Brinell), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore D)

- easy and convenient operation

- Memory capacity: max. 600 groups with 1 - 32 measurement values each (includes the following information: date, average, impact device, number of impacts, material, measurement values)

- Upper and lower limits adjustable with acoustic signal when exceeded

- Measurements possible at any angle (even upside down)

- Calibration function

- 128 x 64 dot matrix LCD: Display of all functions and parameters + backlight

- PC data transfer via USB to DataView Software or MS Hyperterminal for storage and printing

- Automatic shutdown for energy saving

Applications

- Measurements on steel, cast iron, tool and stainless steel, gray and nodular cast iron, brass, bronze, aluminum and copper wrought alloys

- Measurements on large and small cavities, bearings, heavy workpieces, permanently mounted parts

- Damage analysis on pressure vessels, steam generators, etc.

- Material identification

Additional equipment

- additional impact devices for special applications

- Support rings (12 pieces) for convex and concave surfaces

Standard delivery scope

- Hardness tester HardyTest D700 with impact device type D

- Cleaning brush

- Small support ring

- Test block approx. 800 HLD

- Instruction manual

- USB cable with software USB stick

- Charger

- Paper for the printer

- Durable plastic carrying case

Special accessories

- additional impact devices

- Set support rings for measurements on curved surfaces with a radius of less than 30 mm. Facilitate optimal positioning on the test piece. Available in 12 different variations.

Downloads

pdf - 858 KB

pdf - 2 MB

Specifications

| Hardness Units | HL (Leeb), HB (Brinell), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore D) |

| Measuring Range | 170 - 960 HLD |

| Measurement Accuracy | ± 0.75% (related to HL = 800 ± 6 HL) |

| Measurement Direction | 360° |

| Standard Impact Device | D |

| Data Storage Capacity | max. 500 groups (relative to the number of measurements 1-32 pcs.) |

| Statistics | Group number, date, mean value, impact device, number of impacts, material, measurement values |

| Setting Desired Limit Range | acoustic alarm signal when exceeding the set min. and max. limits |

| Minimum Test Piece Weight | > 5 kg solid material; 2-5 kg on stable base; < 2 kg with coupling paste |

| Data Storage | manual or automatic |

| Data Transfer | USB cable and USB stick with software |

| Display | Dot matrix LCD, 128 × 64 dots |

| Backlight | On / Off |

| Menu Language | English/German/French/Italian/Spanish |

| Battery Capacity | 150 hours (without backlight and printing) |

| Power Supply | Integrated and replaceable battery pack (6V NI-MH) with charger (9 V/500 mA) |

| Printer Paper (L x W) | 57.5 (± 0.5 mm) x 30 mm |

| Relative Humidity | ≤ 90% |

| Operating Temperature | -10°C to +50°C |

| Weight | 340 g (with batteries) |

| Dimensions (L x W x H) | 212 x 80 x 32 mm |

All SaluTron® measuring devices comply with national (DIN) and international (ISO, BS, ASTM) standards and have the CE mark.

Subject to technical changes.

Impact devices

| Impact Device | D, DC, DL | D+15 | C | G | |

|---|---|---|---|---|---|

| Impact Energy | 11 mJ | 11 mJ | 2.7 mJ | 90 mJ | |

| Weight of Impact Body | D+DC: 5.5 g DL: 7.2 g | 7.8 g | 3.0 g | 20.0 g | |

| Hardness of Test Tip | 1600 HV | 1600 HV | 1600 HV | 1600 HV | |

| Diameter of Test Tip | 3 mm | 3 mm | 3 mm | 5 mm | |

| Material of Test Tip | Tungsten Carbide | Tungsten Carbide | Tungsten Carbide | Tungsten Carbide | |

| Impact Device Diameter | 20 mm | 20 mm | 20 mm | 30 mm | |

| Impact Device Length | D: 147 mm DC: 86 mm DL: 203 mm | 162 mm | 141 mm | 254 mm | |

| Impact Device Weight | 50 g | 80 g | 75 g | 250 g | |

| Max. Hardness of Test Piece | 940 HV | 940 HV | 1000 HV | 650 HB | |

| Average Roughness of Test Piece Surface Ra | 1.6 µm | 1.6 µm | 0.4 µm | 6.3 µm | |

| Minimum Weight of Test Piece | |||||

| direct measurement | > 5 kg | > 5 kg | > 1.5 kg | > 15 kg | |

| on solid base | 2-5 kg | 2-5 kg | 0.5-1.5 kg | 5-15 kg | |

| Coupling with Coupling Paste | 0.05-2 kg | 0.05-2 kg | 0.02-0.5 kg | 0.5-5 kg | |

| Minimum Thickness of Test Piece | |||||

| with close coupling | 5 mm | 5 mm | 1 mm | 10 mm | |

| Minimum Layer Thickness for Surface Hardening | ≥ 0.8 mm | ≥ 0.8 mm | ≥ 0.2 mm | ≥ 1.2 mm | |

| Size of Impact Impression | |||||

| Hardness 300 HV | Ø - Impression | 0.54 mm | 0.54 mm | 0.38 mm | 1.03 mm |

| Impression Depth | 24 µm | 24 µm | 12 µm | 53 µm | |

| Hardness 600 HV | Ø - Impression | 0.54 mm | 0.54 mm | 0.32 mm | 0.90 mm |

| Impression Depth | 17 µm | 17 µm | 8 µm | 41 µm | |

| Hardness 800 HV | Ø - Impression | 0.35 mm | 0.35 mm | 0.35 mm | - |

| Impression Depth | 10 µm | 10 µm | 7 µm | - | |

| Application of Impact Devices | |||||

| Impact Device D | Standard impact device for most hardness testing tasks | ||||

| Impact Device DC | Extremely short, for measurements in holes, cylinders or internal measurements on workpieces | ||||

| Impact Device DL | Diameter of the tube in the front part: 2.78 mm; for measurements in tight inaccessible places and recesses | ||||

| Impact Device D+15 | Particularly narrow attachment with recessed coil for measurements in grooves and recesses, same properties as Type D; only for steel | ||||

| Impact Device C | Reduced impact energy, approx. 1/4 of Type D; for surface-hardened workpieces, coatings, thinly coated or impact-sensitive parts (low impression depths) | ||||

| Impact Device G | Enlarged impact body with increased impact energy (approx. 9 times larger than Type D); only small damage to the surface; only for measurements in the Brinell range; for solid material, heavy castings and forgings | ||||

| Impact device type | Hardness value of the Leeb standard hardness block | Deviation from the displayed value | Repeatability |

|---|---|---|---|

| D | 760±30 HLD 530±40 HLD | ±6 HLD ±10 HLD | 6 HLD 10 HLD |

| DC | 760±30 HLDC 530±40 HLDC | ±6 HLDC ±10 HLDC | 6 HLD 10 HLD |

| DL | 878±30 HLDL 736±40 HLDL | ±12 HLDL | 12 HLDL |

| D+15 | 766±30 HLD+15 544±40 HLD+15 | ±12 HLD+15 | 12 HLD+15 |

| G | 590±40 HLG 500±40 HLG | ±12 HLG | 12 HLG |

| C | 822±30HLC 590±40HLC | ±12 HLC | 12 HLC |

Subject to technical changes.

Material and hardness values

| Material | Hardness unit | Impact device | ||||

|---|---|---|---|---|---|---|

| D/DC | D+15 | C | G | DL | ||

| Steel, Cast steel | HRC | 20-68.5 | 19.3-67.9 | 20.0-69.5 | - | 20.7-58.7 |

| HRB | 38.4-99.6 | - | - | 47.7-99.9 | - | |

| HB | 127-651 | 80-638 | 80-683 | 90-646 | 81-646 | |

| HV | 83-976 | 80-937 | 80-996 | - | 80-881 | |

| HS | 32.2-99.5 | 33.3-99.3 | 31.8-102.1 | - | - | |

| Tool steel | HRC | 20.4-67.1 | 19.8-68.2 | 20.7-68.2 | - | - |

| HV | 80-898 | 80-935 | 100-941 | - | - | |

| Hammered steel | HB | 143-650 | - | - | - | - |

| Stainless steel | HRB | 46.5-101.7 | - | - | - | - |

| HB | 85-655 | - | - | - | - | |

| HV | 85-802 | - | - | - | - | |

| Gray cast iron | HRB | - | - | - | - | - |

| HB | 93-334 | - | - | 92-326 | - | |

| HV | - | - | - | - | - | |

| Nodular cast iron | HRC | - | - | - | - | - |

| HB | 131-387 | - | - | 127-364 | - | |

| HV | - | - | - | - | - | |

| Aluminum alloys | HB | 19-164 | - | 23-210 | 32-168 | - |

| HRB | 23.8-84.6 | - | 22.7-85.0 | 23.8-85.5 | - | |

| Brass | HB | 40-173 | - | - | - | - |

| HRB | 13.5-95.3 | - | - | - | ||

| Bronze | HB | 60-290 | - | - | - | - |

| Copper wrought alloys | HB | 45-315 | - | - | - | - |

| No. | Code | Type | Drawing | Use |

|---|---|---|---|---|

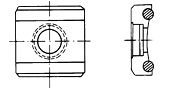

| 1 | 03-03,7 | Z10-15 |  | Measurements on cylindrical outer surfaces R10-R15 |

| 2 | 03-03,8 | Z14,5-30 | Measurements on cylindrical outer surfaces R14,5-R30 | |

| 3 | 03-03,9 | Z25-50 | Measurements on cylindrical outer surfaces R25-R50 | |

| 4 | 03-03,10 | HZ11-13 |  | Measurements on cylindrical inner surfaces R11-R13 |

| 5 | 03-03,11 | HZ12,5-17 | Measurements on cylindrical inner surfaces R12,5-R17 | |

| 6 | 03-03,12 | HZ16,5-30 | Measurements on cylindrical inner surfaces R16,5-R30 | |

| 7 | 03-03,13 | K10-15 |  | Measurements on spherical outer surfaces SR10-SR15 |

| 8 | 03-03,14 | K14,5-30 | Measurements on spherical outer surfaces SR14,5-SR30 | |

| 9 | 03-03,15 | HK11-13 |  | Measurements on spherical inner surfaces SR11-SR13 |

| 10 | 03-03,16 | HK12,5-17 | Measurements on spherical inner surfaces SR12,5-SR17 | |

| 11 | 03-03,17 | HK16,5-30 | Measurements on spherical inner surfaces SR16,5-SR30 | |

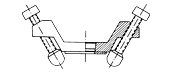

| 12 | 03-03,18 | UN |  | Measurements on cylindrical outer surfaces, adjustable radius R10-∞ |

Subject to technical changes.

Areas of application of hardness testing devices

- Manufacture of metallic components and rubber components

- Mechanical engineering

- Research and development

- Solid state physics