HardyTest D100

The hardness testing device HardyTest D100 is a handheld device with an integrated impact device type D for individual use on site

The size of the hardness testing device is very small and handy, making it ideal for use on large and tight parts. It is perfectly suitable for simple hardness measurements.

The hardness testing device HardyTest D100 is applicable for almost all hardness measurements on ferrous and non-ferrous metals. For use in the power plant industry, petrochemical industry, apparatus, vehicle and mechanical engineering, quality control, steelworks, and more, the HardyTest D100 has proven to be excellent.

Properties

- stable handheld device

- integrated impact device type D

- small, handy, ideal for measurements on difficult-to-access components

- easy operation

- for all metallic materials

- large measuring range: 200 - 960 HLD

- measurements possible in any position

- conversion into other hardness units: HB (Brinell), HRA (Rockwell A), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore)

- high accuracy: ± 0.75 % at 800 HLD

- automatic on and off

- recalibration possible

- compliance with ASTM standard

Applications

- Measurements on steel, cast iron, tool steel, stainless steel, grey and nodular cast iron, brass, bronze, aluminum and copper wrought alloys

- Measurements on large and small cavities, bearings, heavy workpieces, permanently mounted parts

- Damage analysis on pressure vessels, steam generators, etc.

- Material identification through hardness testing

Additional equipment

- Support rings (12 pieces) for convex and concave surfaces

Standard delivery scope

- Device HardyTest D100

- Test block approx. 800 HLD

- Small support ring

- Battery charger

- 9V E-Block accu rechargeable / 9V E-block battery (alkaline)

- Cleaning brush

- User manual

- Sturdy plastic carrying case

Special accessories

- Set of support rings for measurements on curved surfaces with a radius of less than 30 mm. Facilitate optimal positioning on the test piece. Available in 12 different variations.

Downloads

pdf - 5 MB

pdf - 3 MB

Specifications

| Display | LCD, 10 mm high |

| Accuracy | ± 0,75 % (related to HL = 800) |

| Measuring range | 200 - 960 HL |

| Hardness Scales | HL / HRC / HRB / HB / HV / HC |

| Materials | 9 different metals |

| Data memory | 99 measurements |

| Impact device | type D |

| Power supply | DC 9V |

| Dimensions (L x B x H) | 100 x 60 x 33 mm |

| Weight | 150 g |

All SaluTron® gauges correspond to national (DIN) and international (ISO, BS, ASTM) norms and possess the CE-sign.

Specifications are subject to change without prior notice.

Material and hardness values

| Material | HRC | HRB | HRA | HB | HV | HS |

| Steel/Cast Steel | 20 - 68 | 60 - 100 | 59 - 86 | 80 - 650 | 80 - 940 | 32 - 100 |

| Tool Steel | 20 - 68 | - | - | - | 80 - 940 | - |

| Stainless Steel | 20 - 62 | 46 - 100 | - | 80 - 650 | 80 - 800 | - |

| Gray Cast Iron | - | - | - | 90 - 380 | - | - |

| Nodular Cast Iron | - | - | - | 90 - 380 | - | - |

| Aluminum Casting Alloys | - | - | - | 20 - 160 | - | - |

| Brass | - | 13 - 95 | - | 14 - 170 | - | - |

| Bronze | - | - | - | 60 - 290 | - | - |

| Copper | - | - | - | 45 - 315 | - | - |

The ranges correspond to the application limits of static test methods.

Subject to technical changes.

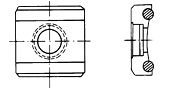

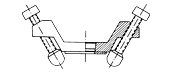

| No. | Code | Type | Drawing | Use |

|---|---|---|---|---|

| 1 | 03-03,7 | Z10-15 |  | Measurements on cylindrical outer surfaces R10-R15 |

| 2 | 03-03,8 | Z14,5-30 | Measurements on cylindrical outer surfaces R14,5-R30 | |

| 3 | 03-03,9 | Z25-50 | Measurements on cylindrical outer surfaces R25-R50 | |

| 4 | 03-03,10 | HZ11-13 |  | Measurements on cylindrical inner surfaces R11-R13 |

| 5 | 03-03,11 | HZ12,5-17 | Measurements on cylindrical inner surfaces R12,5-R17 | |

| 6 | 03-03,12 | HZ16,5-30 | Measurements on cylindrical inner surfaces R16,5-R30 | |

| 7 | 03-03,13 | K10-15 |  | Measurements on spherical outer surfaces SR10-SR15 |

| 8 | 03-03,14 | K14,5-30 | Measurements on spherical outer surfaces SR14,5-SR30 | |

| 9 | 03-03,15 | HK11-13 |  | Measurements on spherical inner surfaces SR11-SR13 |

| 10 | 03-03,16 | HK12,5-17 | Measurements on spherical inner surfaces SR12,5-SR17 | |

| 11 | 03-03,17 | HK16,5-30 | Measurements on spherical inner surfaces SR16,5-SR30 | |

| 12 | 03-03,18 | UN |  | Measurements on cylindrical outer surfaces, adjustable radius R10-∞ |

Subject to technical changes.

Areas of application of hardness testing devices

- Manufacture of metallic components and rubber components

- Mechanical engineering

- Research and development

- Solid state physics