Hardness testing device with integrated impact device type D and/or DL

HardyTest 1800B

The hardness testing device HardyTest 1800B allows you to perform precise hardness measurements even in very small and thin areas (e.g. on gear flanks). Due to its compact design, it is always ready to use and can be carried in a pocket, for example. Nevertheless, it meets all the requirements of a modern hardness testing device. For example, all common hardness units can be displayed.

Properties

- 2 in 1 Impact Device D + DL for measurements in small or hard-to-reach places

- Screw-on DL probe (Ø 4 mm, length 50 mm) for hard-to-reach places

- Wide measuring range

- Easy to calibrate

- Very large memory capacity

- Battery rechargeable via USB cable on PC

- Can be used under extreme conditions (-40°C to 80°C)

- Statistical calculation of mean, minimum, and maximum

- Display, print, and delete measurement data (print via Bluetooth mini printer)

- Data transfer to PC

- Software for data analysis

- Automatic shutdown for energy saving

Applications

- Measurements on steel, cast iron, tool and stainless steel, gray and nodular cast iron, brass, bronze, aluminum and copper wrought alloys

- Measurements on large and small cavities, bearings, heavy workpieces, permanently mounted parts

- Damage analysis on pressure vessels, steam generators, etc.

- Material identification

Standard delivery scope

- Hardness tester HardyTest 1800B® with integrated impact device type D

- Test block approx. 800 HLD

- Cleaning brush

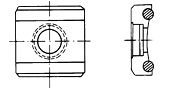

- Small support ring

- Charger

- USB cable with software

- Operating instructions

- Durable plastic carrying case

Special accessories

- screw-on impact device type DL

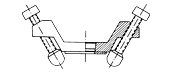

- Set support rings for measurements on curved surfaces with a radius of less than 30 mm. Facilitate optimal positioning on the test piece. Available in 12 different variations.

Downloads

Data Sheet HardyTest 1800B (PDF)

pdf - 921 KB

User Manual HardyTest 1800B (PDF)

pdf - 4 MB

Specifications

| Hardness Units | HL (Leeb), HB (Brinell), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore D), σb Tensile Strength |

| Measuring Range | 170-960 HLD / 80-940 HV (on steel) |

| Materials | Steel/ Cast steel, Tool steel, Stainless steel, Gray cast iron, Ductile iron, Aluminum cast alloys, Brass, Bronze, Copper |

| Measurement Accuracy | ±6 HL at 800 HL |

| Workpiece Radius | D: min. 20 mm, DL: min. 4 mm |

| Minimum Weight of Workpiece | 5 kg; 2-5 kg on stable base; 2 kg with coupling paste |

| Minimum Thickness of Workpiece | 3 mm with coupling paste |

| Minimum Roughness of Workpiece | 1.6 µm (Ra) |

| Minimum Hardness Depth | 0.8 mm |

| Impression Depth | 300 HV=24 µm, 600 HV=17 µm, 800 HV=10 µm |

| Impact Device Testing Direction | 0 - 360° |

| Functions | Value correction and calibration, Setting of impact device, Material, Hardness unit and Impact direction, Automatic on and off, Upper and lower limit adjustable (Warning by beep for over/under limit) |

| Statistics | Mean value, Maximum value, Minimum value |

| Memory | 4 blocks for 4000 values |

| Data Transfer to PC | Via USB, Evaluation by software |

| Display | OLED digital screen, adjustable display backlight |

| Power Supply | 3.7 V Lithium-Ion Battery |

| Environmental Conditions | -40°C to 80°C, ≤ 80% rel. humidity |

| Standards | GB/T 17394-1998, ASTM A956, DIN 50156 |

| Dimensions | 148 x 44 x 22 mm, Length with impact device DL: 205 mm |

| Weight | 110 g |

All SaluTron® measuring devices comply with national (DIN) and international (ISO, BS, ASTM) standards and have the CE mark.

Subject to technical changes.

| No. | Code | Type | Drawing | Use |

|---|---|---|---|---|

| 1 | 03-03,7 | Z10-15 |  | Measurements on cylindrical outer surfaces R10-R15 |

| 2 | 03-03,8 | Z14,5-30 | Measurements on cylindrical outer surfaces R14,5-R30 | |

| 3 | 03-03,9 | Z25-50 | Measurements on cylindrical outer surfaces R25-R50 | |

| 4 | 03-03,10 | HZ11-13 |  | Measurements on cylindrical inner surfaces R11-R13 |

| 5 | 03-03,11 | HZ12,5-17 | Measurements on cylindrical inner surfaces R12,5-R17 | |

| 6 | 03-03,12 | HZ16,5-30 | Measurements on cylindrical inner surfaces R16,5-R30 | |

| 7 | 03-03,13 | K10-15 |  | Measurements on spherical outer surfaces SR10-SR15 |

| 8 | 03-03,14 | K14,5-30 | Measurements on spherical outer surfaces SR14,5-SR30 | |

| 9 | 03-03,15 | HK11-13 |  | Measurements on spherical inner surfaces SR11-SR13 |

| 10 | 03-03,16 | HK12,5-17 | Measurements on spherical inner surfaces SR12,5-SR17 | |

| 11 | 03-03,17 | HK16,5-30 | Measurements on spherical inner surfaces SR16,5-SR30 | |

| 12 | 03-03,18 | UN |  | Measurements on cylindrical outer surfaces, adjustable radius R10-∞ |

Subject to technical changes.

Areas of application of hardness testing devices

- Manufacture of metallic components and rubber components

- Mechanical engineering

- Research and development

- Solid state physics