CoatMaster Flex

Non-contact measurement of layer thickness

The CoatMaster Flex measures without dangerous radiation sources, such as laser or X-rays, and is based on the principle of thermal layer testing. A flash lamp is used as an excitation source to heat the coating. After a short pulse-like heating of the coating by a few degrees Celsius, cooling and heat conduction into deeper areas of the coating and into the substrate material occur. The detected thermal radiation is contactlessly captured, converted, and digitized with an infrared sensor. By calibrating the coating and the substrate material, the CoatMaster Flex can perform a non-contact determination of the layer thickness using this measurement principle (Reinke & Bariska, 2010, pp. 10-13).

Efficient: by constantly and easily monitoring the coating process, coating materials can be significantly saved and costs reduced. The use of the CoatMaster Flex layer thickness gauge in a production process pays off in a short period of time.

Properties

- Non-contact measurement of layer thickness

- also for wet paints before drying and powder coatings before baking

- distance and angle-independent measurement

- on all colors (including white)

- up to 30% savings on coating material and rejects

- rapid and secure control of coating processes

- also on fast-moving parts and hard-to-reach areas

- Real-time data access via ERP and browser

- extremely precise measurement even on rough (e.g. sandblasted) surfaces

Applications

The device is particularly used for quality control in the ongoing production of high-quality products in the automotive industry, such as bearing shells, pistons, and vibration dampers. Both wet and powder coatings, as well as dry coatings, can be measured with the CoatMaster Flex. For powder applications, the CoatMaster Flex is already pre-calibrated and only needs to be selected between two selectable levels (light/dark). For wet paint applications, a simple calibration needs to be performed (per color, or per color group). The use of the system leads to sustainable improvement of product quality in many industries (Fraunhofer Society, 2017).

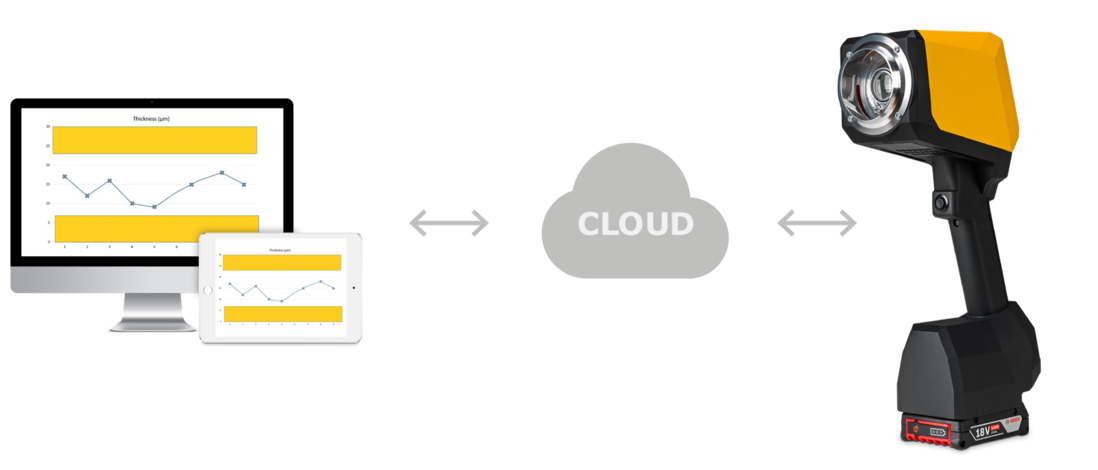

The device is equipped with a WLAN module. It is necessary to establish an active internet connection with the device for operation. The measurements are carried out on-site and sent to a central computer via the internet for the calculation of the coating thickness. The thickness value calculated in milliseconds is then transferred back to the handheld device and displayed on the screen. All other data such as formed measurement blocks and corresponding statistical values are also stored on the central server and can be accessed at any time with the handheld device.

Standard delivery scope

- Handheld device CoatMaster Flex

- 2 x rechargeable supply batteries

- Charger

- User manual

- Sturdy service case

Special accessories

- mobile WiFi router for use with a SIM card

- local server mini PC with coatmaster Flex Server software pre-installed including one Fles operating license

Downloads

pdf - 947 KB

pdf - 2 MB

Specifications

| Measuring range Wet paint Powder coating uncured Powder coating cured | 1 to 400 µm 1 to 400 µm 1 to 1.000 µm |

| Measuring time | 0.25 s |

| Measuring distance | 2 to 15 cm |

| Angle tolerance | ± 70° |

| Measuring on moving parts | yes |

| Relative Standard Deviation | 1% |

| Time between two measurements | approx. 2 s |

Specifications are subject to change without prior notice.

Use of CoatMaster Flex

- Automotive

- Railway

- Aerospace

- Construction

- Furniture

- Aluminum profiles

- Wind power

- Pipelines

- Medical technology